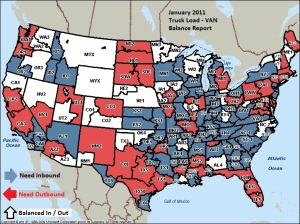

This map explains a little about the complexity and all the moving parts associated with a Global Supply Chain. The business intelligence solutions required to help understand this better needs to be matched in sophistication to the complexity that undoubtedly exists.

Our best-in-class, web-based system makes every aspect of transportation management efficient and seamless. Our data entry portal makes short work out of otherwise tedious administrative tasks by pre-configuring the workflow process to match your specific needs. In real time, we’re able to evaluate special equipment requirements, assess safety and environment ratings, insurance coverage, and certifications. We simultaneously optimize inbound and outbound shipments, to ensure we’re helping you make the right decisions and minimize costs at every turn.

Business Value Logistics incorporates industry tools and technology to integrate logistic systems to businesses around the globe. With tools to globally track both inbound and outbound shipments across all modes, we’re able to optimize current routing systems. This technology allows companies to make changes to the central in-house online hub that will be seen throughout the logistics system. And through our mobile apps, employees can monitor the supply chain right on their smartphone or tablet. This eliminates the need to update logistic changes on multiple systems and greatly decreases the risk of confusion from information not syncing.

Give us three months of data, and we will provide you with shipping solutions to save you money. An optimization study will help to ensure that shipping patterns, sizes and configurations are working together to minimize effort, shipping times and costs. We will review current methods and modes, analyze results, and provide recommendations to increase efficiency, reduce cost, and ensure the timely delivery of goods.

Contact Us For More Information

Business Value Logistics . 1517 Hunt Club Blvd . Gallatin, TN 37066

615.928.2300 or email info@bvlintl.com

Filed under: Uncategorized